Common Conveyor Chain Failure Mechanisms

Common Conveyor Chain Failure Mechanisms?

In most conveyor systems, there are four main types of conveyor chains, each with its own specific application characteristics:

Tensile Failure

Stretch failure may be due to the conveyor chain being overstretched, causing the chain to not work as expected, or to break completely.

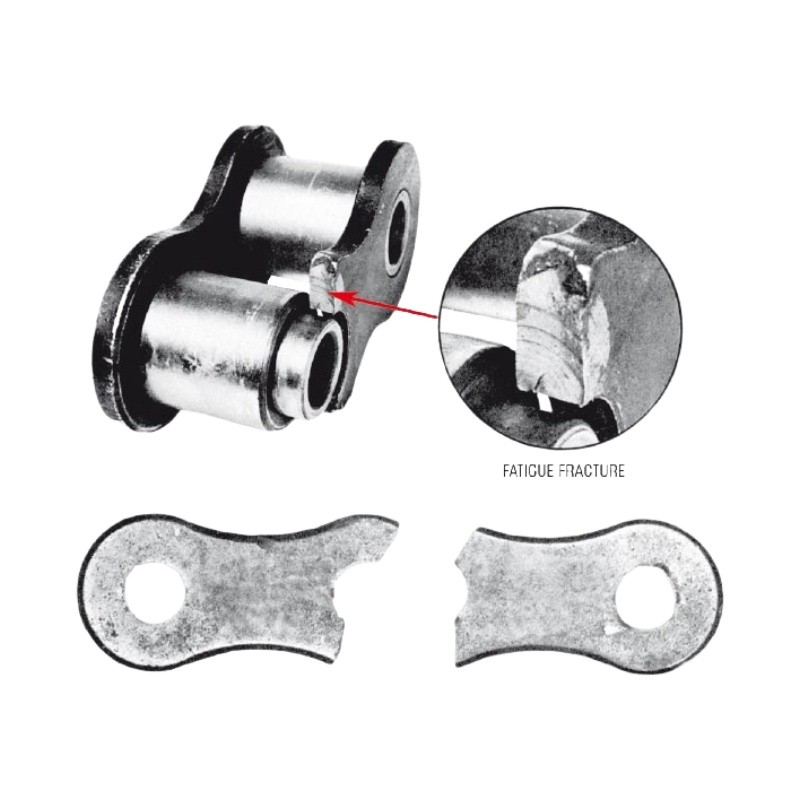

Fatigue Failure

When the conveyor chain is overloaded by cyclic tension at a load below the yield strength, microscopic cracks are generated in the link plates or side bars due to excessive weight. These cracks can grow, leading to fatigue failure, which can lead to incorrect function and eventual fracture.

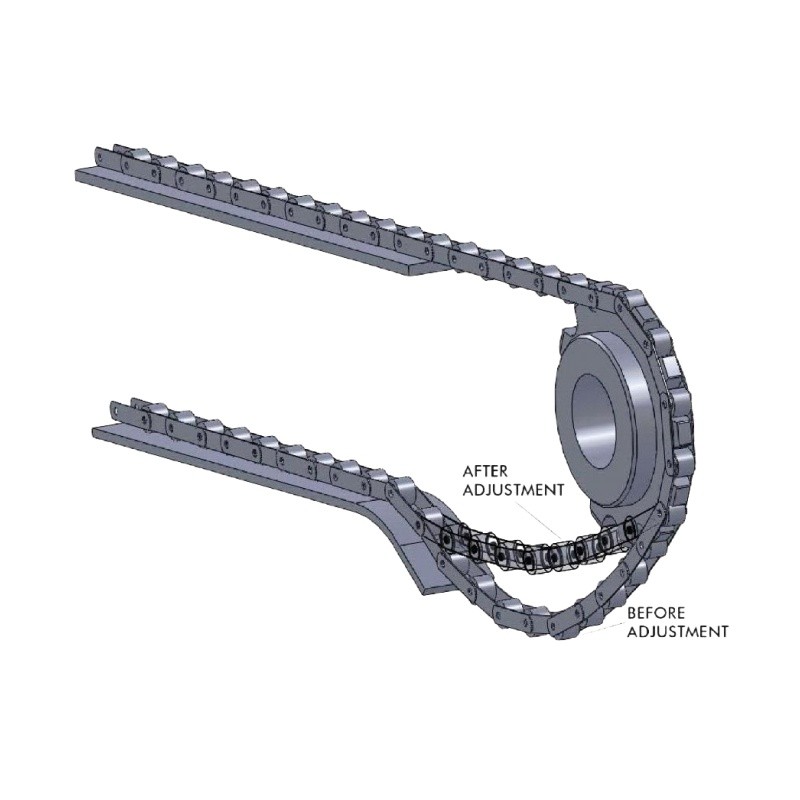

Wear Failure

Wear failure is the result of wear and corrosion that causes the conveyor chain to stretch without proper stretching. This often causes the chain to become too large to fit the sprockets of the conveyor system, or to maintain proper spacing and timing. Wear that occurs between rollers and bushings, between link plates, or between side bars and guide rails will eventually cause chain failure.

For over fourteen years, CTS® has dedicated itself to crafting top-quality roller chain and drive components. Our specialization extends to providing superior power transmission parts and custom-designed products. If you're seeking a reliable Roller Chain solution, look no further. With a full range of ANSI Roller Chains and Metric Roller Chains at your disposal, our experienced team is ready to assist you in finding the perfect fit for your needs. Trust CTS® to deliver excellence and efficiency every step of the way.

To browse our excellent products, please visit our ChinaTransmissions.com or contact us via email at info@chinatransmissions.com or call 0086-18667944319(WhatsApp/WeChat).

If you have any questions, please feel free to contact us, CTS® professional technicians will be happy to help you!